There are moments that are unique because they are unrepeatable, and then there are moments that are just as unique, but renew their singularity every day.

Such is the case of the making of Parmigiano Reggiano, an activity that has been repeated every morning for nine centuries in the dairies of Emilia.

In fact, Parmigiano Reggiano is produced exclusively in the provinces of Parma, Reggio Emilia, Modena and parts of the provinces of Mantua and Bologna, in the plains, hills and mountains between the Po and Reno rivers.

In this area there are about four thousand farms where the cows are fed exclusively with fodder produced in the area.

A deep bond with an environment and landscape that is respected and protected, contributing to the formation of those unique qualities that characterise the “king of cheeses”.

How is a wheel of Parmigiano Reggiano cheese made?

But how is Parmesan cheese actually made? Where does it get the uniqueness that makes it one of the most famous and appreciated cheeses in the world?

Every day, the milk from the evening milking is left to rest in large vats until morning, when the fat part, destined for the production of butter, spontaneously separates.

The skimmed milk from the evening milking, together with the whole milk from the morning milking, fresh from the farms, is then poured into the typical inverted bell-shaped copper vats, with the addition of calf rennet and whey starter, rich in natural milk enzymes from the previous day’s processing.

At this point, the fire enters the scene for a cooking process that reaches 55 degrees centigrade, at the end of which the granules fall to the bottom of the vat, forming a single mass.

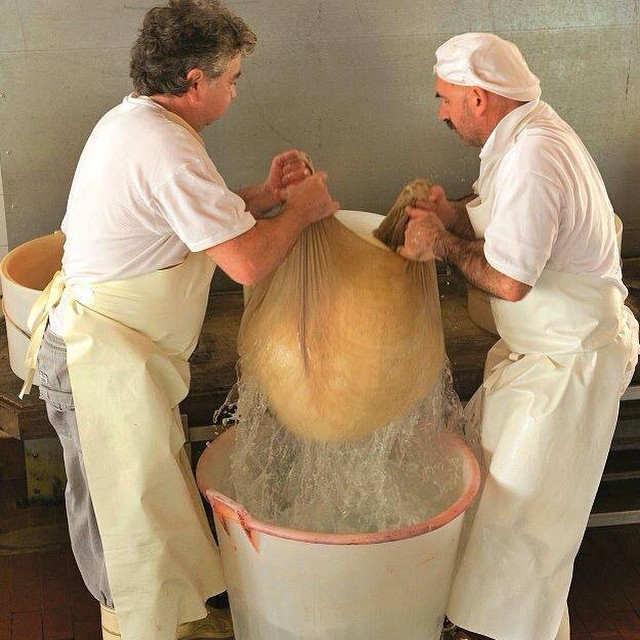

After about fifty minutes, the cheese is removed by the cheese-makers with skilful movements.

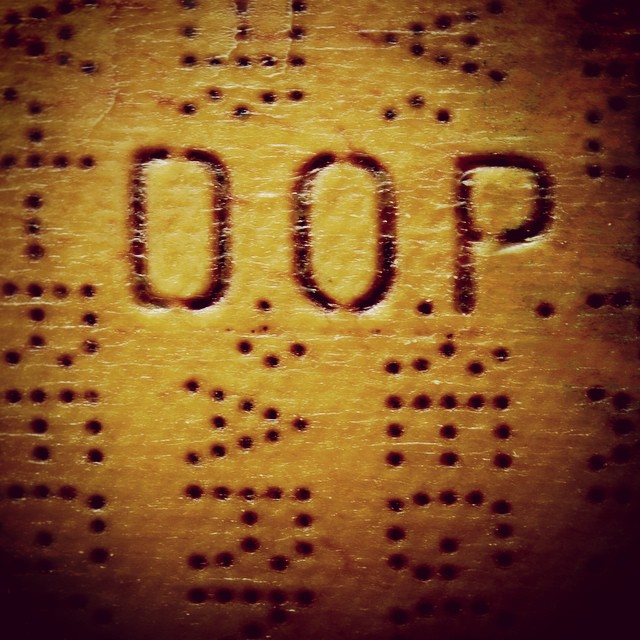

Cut into two pieces, wrapped in the typical cloth and numbered with a progressive number – which becomes its true identity card – the cheese is now ready to be placed in a ‘fascera‘, which gives it its final shape.

Then comes the salting process: the cheeses are immersed in a saturated solution of water and salt. It’s a process of salting by absorption, which takes just under a month to complete and opens up the fascinating phase of maturing.

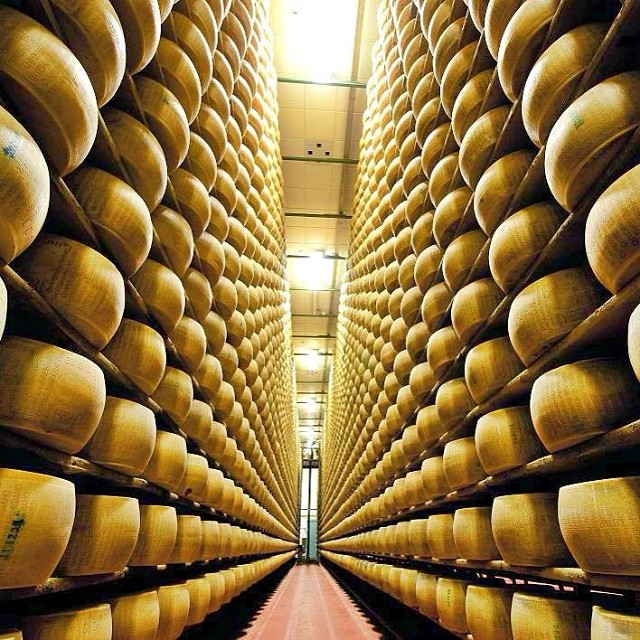

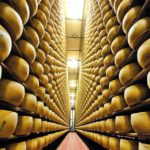

Imagine silent warehouses filled to the ceiling with thousands of wheels of Parmesan cheese, like Gothic cathedrals of food, where the fruits of an entire region’s labour rest in silence.

There is something solemn about the ripening of Parmigiano Reggiano.

Left to rest on wooden boards, the outer part of the cheese dries to form a natural rind, untreated and therefore perfectly edible.

The history of Parmigiano Reggiano is long, but it is also slow, following the natural rhythm of the seasons. The minimum maturing period is twelve months. Only then it is possible to say whether each wheel will be able to keep the name that was imprinted on it at the time of its birth.

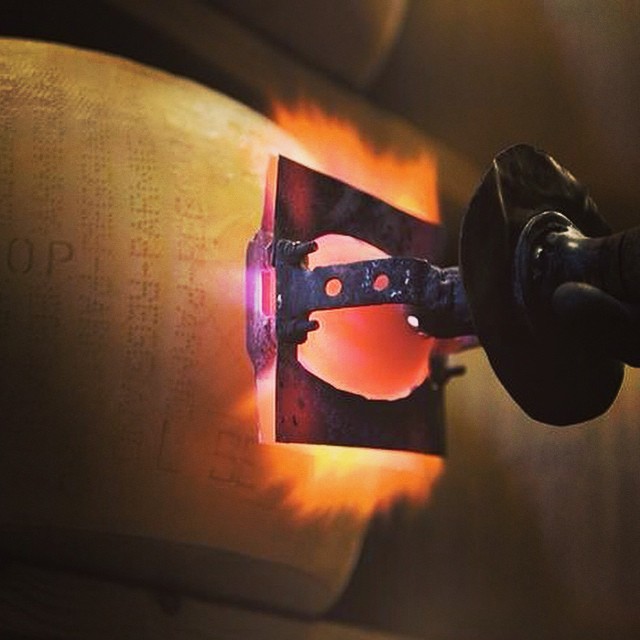

The experts of the Consorzio examine the wheels one by one and, using traditional methods, decide which wheels will receive the product guarantee certificate.

It is at this point that the cheese acquires its typical crumbly grain structure, together with all the qualities that make it an easily digestible and nutritious cheese.

Thanks to the Consorzio del Parmigiano Reggiano and the Consorzio Vacche Rosse for the photographs.

Author

Walter Manni

Explorer and Adventurer: loves sailing the oceans, climbing the highest mountains and surfing on the waves of the web

You may also like

Emilia-Romagna’s traditional cheeses

by Maria Grazia Masotti /// March 14, 2024

5 food experiences not to be missed in Emilia Romagna

by Elisa Mazzini /// September 6, 2016

Interested in our newsletter?

Every first of the month, an email (in Italian) with selected contents and upcoming events.

Emilia-Romagna PDOs and PGIs: a journey through Italy’s Food Valley

by Walter Manni /// January 16, 2024

by Walter Manni ///